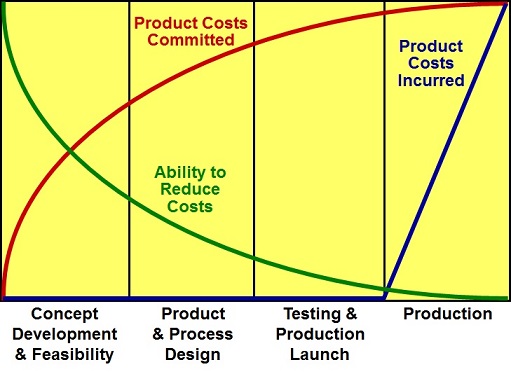

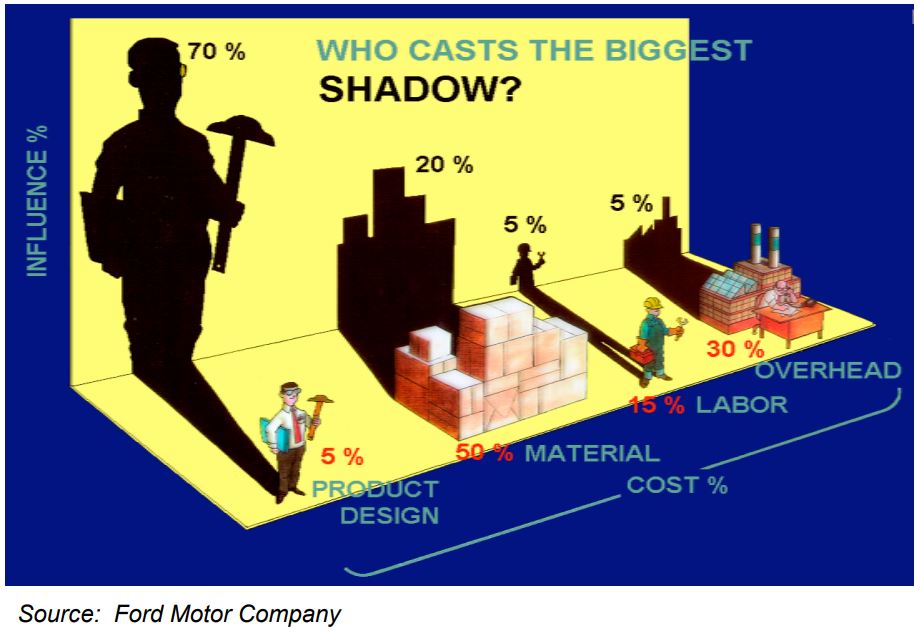

It is a well-accepted rule-of-thumb that as much as 75% of the cost of a product is locked in during the concept design phase. By the time the product reaches production the ability to reduce costs is relatively small, with perhaps just a few percent of the cost available for CR.

In bygone days it was something of a tradition for buyers to try to overturn this accepted wisdom by a process known as “beating-up the supplier”. I even have experience of suppliers being expected to deliver on-going cost reductions year-on-year. The reality is, of course that it is not sustainable for suppliers to continually relinquish their (already competitive) margins and so for them the “race to the bottom” is not at all a viable long-term business strategy.

The illustration below shows how most of the product cost (red curve) is committed in the design stages, whilst the ability to reduce cost (green curve) in the production phase is very small. Unfair, then to demand that cost reduction comes from the manufacturer when it is found that the costs are too high.

Another accepted truism is that in the early stages of development, changes (to the design) can be made at minimal cost. Later on, when in production it can become very expensive to make changes because of the costs committed.

Consider the case of a Plastic Injection Moulded part. If changed during the design cycle a minor change may be dealt with by a few clicks of the mouse. However, once the part is in production the same change could easily involve engineering, design, manufacturing documentation, change control, Change Review & Implementation boards (CRB / CIB), product handbooks and procurement. At the manufacturing end the impact could impact stock control, require a tooling change (and let’s hope for material “off” the tool and not material on!), changes to shot weights and with it process settings such as temperature, cycle time etc. The parts may then have circle back through the formal acceptance processes such as FAI (First Article Inspection) and FFF (Fit, form & Function) testing.

It is critical then that the design (and specifically the concept) is as right as it can be from the off. Why then is Cost Reduction even a thing then if we make every effort to get the design right?

There are a number of potential sources of built-in cost that a thorough Cost Reduction exercise will examine and exploit. These include:

As designers we strive to generate concepts that are the best that they can possibly be at meeting all customer specified technical & commercial requirements. When working Fixed Price design contracts the fixing of specifications is particularly important, as payment is usually linked to the successful completion of milestones. There is nothing simpler at a Concept Ready review than working through a table of requirements and showing how each is met by the proposed concept!

Even when the potential market is thoroughly researched, technical and (more probably) commercial requirements may change over time. The net result is that a design that was once optimised for cost may no longer be so.

So, as long as there are end-users and free-market forces there will always be the possibility of changes to technical or commercial requirements, and with them the necessity for redesign and potentially for Cost Reduction.

To find out more about our Cost Reduction or Cost Avoidance services call us now on 01277 261066 or email us.