I have recently been visiting secondary schools to find the most suitable for my daughter, and I was delighted to see that many have a 3D printer in their Design Technology workshop. With print-to-order giveaways the machines were a great draw for prospective students and parents alike. This is great to see, as it is

In many European countries being an engineer carries a certain kudos, like a lawyer or a doctor. However, here in the UK there exists a strong likelihood that if you tell someone that you’re an engineer they assume that you wield a spanner, crawl under cars or fix washing machines .… Now don’t get me

I saw a comment posted a while ago asking if it is necessary to consider Design for Manufacture when in the early stages of design ….. absolutely! The design itself and the manufacturing technique are so intertwined that to design without manufacture in mind will likely lead to parts that cannot be made within cost targets. It is

SolidWorks or Pro/ENGINEER? At Warley Design our users have been using both for many years. Personally, I formally trained on Pro/ENGINEER in or before 1998 and our employer bought a few seats of SolidWorks in addition in 2005 . When Jon and I set-up Warley Design in 2008 the first license we bought was SolidWorks – not necessarily because it was the

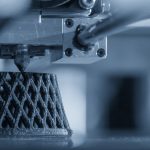

This movie captures the moment we fist assembled some parts made by Rapid Prototyping (RP) techniques. We used SLS to represent the longer part that was designed to be extruded in plastic (rather like plastic conduit), and also to make the end caps which would be made by Plastic Injection Moulding (PIM) in volume. The