The 3D printed car sure is an eye-catching way to show-case a fantastic new technology. It will fire the imagination and enable endless possibilities for personalised vehicles which can be printed before your very eyes in just 44 hours at the single press of a button.

… well, hold on just a minute. Is it really the wonder tool that the movie portrays?

True: it is possible for people to make highly customised parts or assemblies that have been impossible to make in the past. It is important to remember, however, that the combined body and chassis has had to be especially designed for manufacture by this specific Additive Material process – one cannot take conventional parts and simply print them. Exploitation of this new technology requires a whole new approach to design which centres around the integration of numerous parts into as few as possible.

To get the design to the point where it is ready for manufacture took 4 months in this example – roughly equivalent to £33k of 3D CAD design time to get each unique car, plus the cost of making the car itself (cost of carbon-loaded material plus machine time). Not exactly the £7,000 claimed. I doubt very much if this included any engineering time to look at the structural integrity or the road safety issues either.

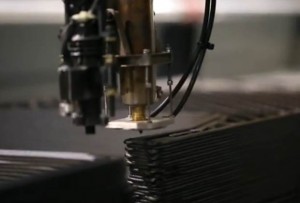

Another important consideration is that although the reporter mentioned the 44 hours print time the post printing finishing and assembly was not declared. The natural surface finish of the AM process would be far from acceptable for the outside of a car and so a great deal of specialised finishing (hand crafting?) would be necessary to render the surface smooth enough for painting. A close-up of the natural finish is shown.

Another important consideration is that although the reporter mentioned the 44 hours print time the post printing finishing and assembly was not declared. The natural surface finish of the AM process would be far from acceptable for the outside of a car and so a great deal of specialised finishing (hand crafting?) would be necessary to render the surface smooth enough for painting. A close-up of the natural finish is shown.

So, interesting show-case for an emerging technology? …. absolutely.

A game changer? Hardly. General Motors will not be losing sleep any time soon.

3D printing is shaping up to be a technology that opens up a world of possibilities in that it enables previously impossible things to be made. It’s also great for as a rough-and-ready representation of a final form and so is really coming into its own when used for rapid prototyping. The slow process times limitations in materials mean that it is likely never to be a contender for making things that are currently manufacturable by traditional volume techniques.

Warley Design offers mechanical design, engineering and product development services to a broad range of industries. If you have a development programme that we can help you with please contact us.