The most cited objections to the take-up of electric vehicles seem to be the purchase cost and the range before the batteries need charging. What’s needed to resolve both issues is a significant breakthrough in battery technology and cost benefits to the manufacture of vehicles and key components through scaling-up production. To a certain extent its the old chicken-and-egg story: no-body is going to scale-up production without a decent order book.

Enter Tesla’s CEO Elon Musk, who also heads up a space travel business SpaceX and is heir apparent to the late Steve Jobs as the best-known tech genius in Silicon Valley.

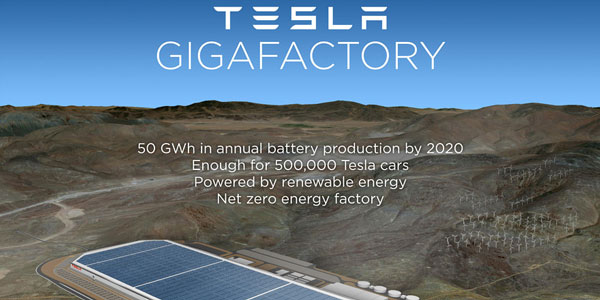

Tesla is leading the field with the construction of its Gigafactory in the Navada desert. The building is so-called because Tesla hopes that, once complete, it will house annual battery production capacity of 35 gigawatt-hours (GWh) of lithium ion batteries, made to power EVs.

There is huge interest in this project for a number of reasons, namely that is it being spearheaded by one of the world’s most innovative and charismatic entrepreneurs and, secondly, the sheer size of the operation being proposed.

Tesla is known for producing high end electric cars and recently also launched the Powerwall – a home battery designed to save electricity generated by solar panels for use outside daylight hours.

The Tesla website states that the company projects it could be building up to 500,000 electric cars per year in the latter years of this decade, and that today’s entire worldwide production of lithium ion batteries would be required to power them. Thus the Tesla Gigafactory has been born of necessity.

Located at the appropriately named Electric Avenue in Sparks, Nevada, work building the Gigafactory started last year with cell production expected to commence in 2017. When the entire factory is finished in 2020 it is expected to be the world’s second largest building by volume – only slightly smaller than Boeing’s Everett, Washington, plant.

The Gigafactory’s massive roof will covered in solar panels helping to achieve the goal that the factory be powered totally by renewable energy sources. Tesla also says “economies of scale, innovative manufacturing, waste reduction and the simple optimization of locating most manufacturing process under one roof” will help drive costs down by 30% making the batteries, and therefore EVs, more affordable.

For so many reasons this trailblazing project is incredibly exciting and we shall be following the Gigafactory’s progress, as well as Mr Musk’s next move, with much interest.

To find out more about our mechanical design & engineering services, call us now on Tel: +44 (0)1277 261066 or email us at info@warleydesign.co.uk